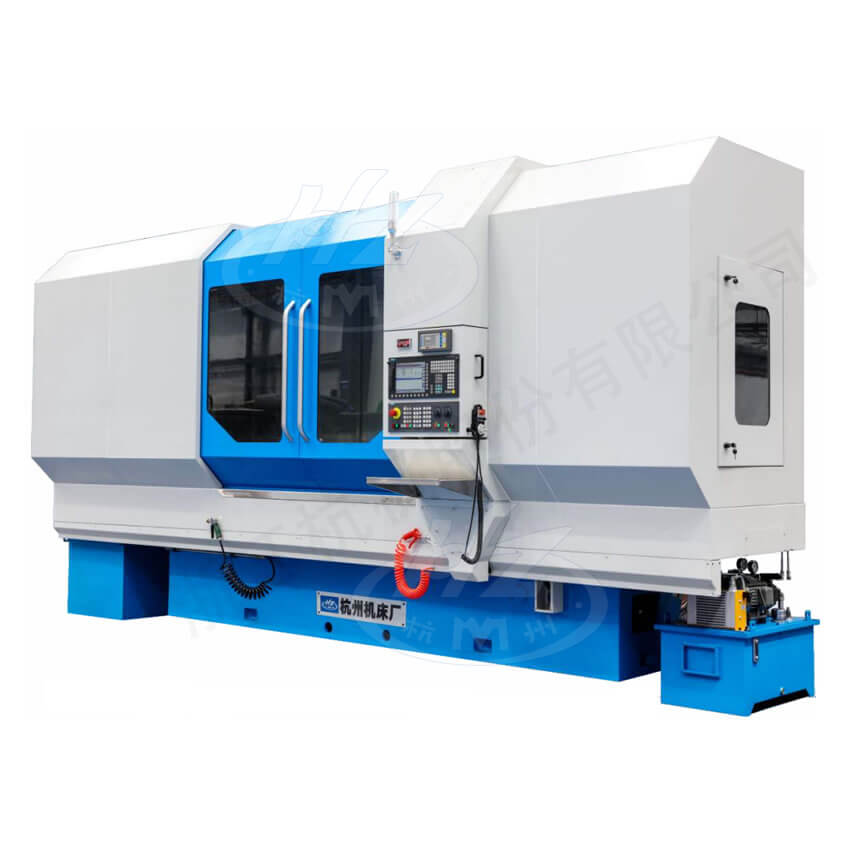

CNC Powerful Forming Grinder

■ Won the second prize of science and technology in China's machinery industry and won the new record list of Chinese Enterprises

■ The middle waist column mobile structure with independent intellectual property rights has high rigidity and high stability (Patent No.: ZL03230376.9)

■ X. Y, Z, V four axis guide has advanced structure and technology, feed sensitive, high machining accuracy.

■ Siemens 828D/840DSL numerical control system is used to control the longitudinal movement of worktable, vertical feed of grinding head, transverse feed of column, continuous dressing shaft and grinding wheel spindle separately or in linkage. It has the compensation function of linear interpolation and circular interpolation, and can realize automatic grinding interpolation.

■ The shaft low pressure gas seal system protects the spindle from high pressure coolant. (Patent No.: 200520100432.6)

■ Temperature control technology of spindle system

■ The application of various shaping and dressing technologies, such as table top diamond roller dressing, diamond pen or diamond disc dressing through y and Z axis linkage, swing dressing, top diamond roller online continuous dressing (CD), has high shaping accuracy.

■ The operation interface of Hangji secondary development: menu type human-computer dialogue interface, graphic display, simple and easy to use.

■ The design of the machine tool is novel, the mandatory safety standard is implemented, and the design of the fully enclosed enclosure meets the requirements of environmental protection.

' != '')}产品特点{/pboot:if}{pboot:if('| Model: | MKL7150×16 | ||

|---|---|---|---|

| Table size (W × L) | mm | 500×1600 | |

| Maximum bearing capacity of worktable | kg | 1500 | |

| Longitudinal movement (X-axis) | Maximum stroke | mm | 1700 |

| Maximum speed | mm/min | 25000 | |

| Minimum feed rate | mm | 0.001 | |

| Vertical feed (Y-axis) | Distance from spindle center to table top | mm | 250-800 |

| Maximum speed | mm/min | 3000 | |

| Minimum feed rate | mm | 0.001 | |

| Lateral movement (Z axis) | Maximum stroke | mm | 420 |

| Maximum speed | mm/min | 3000 | |

| Minimum feed rate | mm | 0.001 | |

Overhead dresser (V-axis) (optional) | Maximum installation width | mm | 160 |

| Tilt axis (A axis) | Corner range | (°) | -20°~ +120° |

| Minimum feed rate mm | mm | 0.001° | |

| Rotary shaft (B-axis) | Corner range | (°) | 0°~ 360° |

| Minimum feed rate mm | mm | 0.001° | |

| Principal axis | Power | kW | 60(Optional44、90、110) |

| Speed | rpm | 0-3000(Optional5000) | |

| Axial jump/radial jump | mm | 0.002 | |

| Grinding wheel size | Outer diameter × width × inner diameter | mm | 400×(10-120)×127mm |

| High pressure cooling | Pressure | bar | >15(It can be selected according to the actual situation) |

| Flow | L/min | >200(It can be selected according to the actual situation) | |

| Positioning accuracy | X,Y, Z axis (full closed loop) | mm | 0.004 |

| Repeat positioning accuracy | X,Y,Z axis (full closed loop) | mm | 0.002 |

The new type of horizontal axis moment table layout is adopted in this series of machine tools. The machine tool uses mature slow feed forming strong grinding technology, which can be directly grinded by blank, with advanced technology, high forming precision, high production efficiency and high automation.

The machine tool is mainly used for high-precision grinding of complex curved surfaces such as arc crown of heavy-duty gas turbine blade, inner and outer circles of guide blade, mounting plate and arc groove. It is especially suitable for surface processing of multi-directional, convex, concave, arc surface and other parts, including forming surfaces of various difficult to machine materials.

The forming wheel is used for grinding with large margin and slow feed force. This series of machine tools are gas turbine, steam turbine, aircraft engine, mold manufacturing and other industries.

■ Won the second prize of science and technology in China's machinery industry and won the new record list of Chinese Enterprises

■ The middle waist column mobile structure with independent intellectual property rights has high rigidity and high stability (Patent No.: ZL03230376.9)

■ X. Y, Z, V four axis guide has advanced structure and technology, feed sensitive, high machining accuracy.

■ Siemens 828D/840DSL numerical control system is used to control the longitudinal movement of worktable, vertical feed of grinding head, transverse feed of column, continuous dressing shaft and grinding wheel spindle separately or in linkage. It has the compensation function of linear interpolation and circular interpolation, and can realize automatic grinding interpolation.

■ The shaft low pressure gas seal system protects the spindle from high pressure coolant. (Patent No.: 200520100432.6)

■ Temperature control technology of spindle system

■ The application of various shaping and dressing technologies, such as table top diamond roller dressing, diamond pen or diamond disc dressing through y and Z axis linkage, swing dressing, top diamond roller online continuous dressing (CD), has high shaping accuracy.

■ The operation interface of Hangji secondary development: menu type human-computer dialogue interface, graphic display, simple and easy to use.

■ The design of the machine tool is novel, the mandatory safety standard is implemented, and the design of the fully enclosed enclosure meets the requirements of environmental protection.

' != '')}■ Won the second prize of science and technology in China's machinery industry and won the new record list of Chinese Enterprises

■ The middle waist column mobile structure with independent intellectual property rights has high rigidity and high stability (Patent No.: ZL03230376.9)

■ X. Y, Z, V four axis guide has advanced structure and technology, feed sensitive, high machining accuracy.

■ Siemens 828D/840DSL numerical control system is used to control the longitudinal movement of worktable, vertical feed of grinding head, transverse feed of column, continuous dressing shaft and grinding wheel spindle separately or in linkage. It has the compensation function of linear interpolation and circular interpolation, and can realize automatic grinding interpolation.

■ The shaft low pressure gas seal system protects the spindle from high pressure coolant. (Patent No.: 200520100432.6)

■ Temperature control technology of spindle system

■ The application of various shaping and dressing technologies, such as table top diamond roller dressing, diamond pen or diamond disc dressing through y and Z axis linkage, swing dressing, top diamond roller online continuous dressing (CD), has high shaping accuracy.

■ The operation interface of Hangji secondary development: menu type human-computer dialogue interface, graphic display, simple and easy to use.

■ The design of the machine tool is novel, the mandatory safety standard is implemented, and the design of the fully enclosed enclosure meets the requirements of environmental protection.

| Model: | MKL7150×16 | ||

|---|---|---|---|

| Table size (W × L) | mm | 500×1600 | |

| Maximum bearing capacity of worktable | kg | 1500 | |

| Longitudinal movement (X-axis) | Maximum stroke | mm | 1700 |

| Maximum speed | mm/min | 25000 | |

| Minimum feed rate | mm | 0.001 | |

| Vertical feed (Y-axis) | Distance from spindle center to table top | mm | 250-800 |

| Maximum speed | mm/min | 3000 | |

| Minimum feed rate | mm | 0.001 | |

| Lateral movement (Z axis) | Maximum stroke | mm | 420 |

| Maximum speed | mm/min | 3000 | |

| Minimum feed rate | mm | 0.001 | |

Overhead dresser (V-axis) (optional) | Maximum installation width | mm | 160 |

| Tilt axis (A axis) | Corner range | (°) | -20°~ +120° |

| Minimum feed rate mm | mm | 0.001° | |

| Rotary shaft (B-axis) | Corner range | (°) | 0°~ 360° |

| Minimum feed rate mm | mm | 0.001° | |

| Principal axis | Power | kW | 60(Optional44、90、110) |

| Speed | rpm | 0-3000(Optional5000) | |

| Axial jump/radial jump | mm | 0.002 | |

| Grinding wheel size | Outer diameter × width × inner diameter | mm | 400×(10-120)×127mm |

| High pressure cooling | Pressure | bar | >15(It can be selected according to the actual situation) |

| Flow | L/min | >200(It can be selected according to the actual situation) | |

| Positioning accuracy | X,Y, Z axis (full closed loop) | mm | 0.004 |

| Repeat positioning accuracy | X,Y,Z axis (full closed loop) | mm | 0.002 |

| Model: | MKL7150×16 | ||

|---|---|---|---|

| Table size (W × L) | mm | 500×1600 | |

| Maximum bearing capacity of worktable | kg | 1500 | |

| Longitudinal movement (X-axis) | Maximum stroke | mm | 1700 |

| Maximum speed | mm/min | 25000 | |

| Minimum feed rate | mm | 0.001 | |

| Vertical feed (Y-axis) | Distance from spindle center to table top | mm | 250-800 |

| Maximum speed | mm/min | 3000 | |

| Minimum feed rate | mm | 0.001 | |

| Lateral movement (Z axis) | Maximum stroke | mm | 420 |

| Maximum speed | mm/min | 3000 | |

| Minimum feed rate | mm | 0.001 | |

Overhead dresser (V-axis) (optional) | Maximum installation width | mm | 160 |

| Tilt axis (A axis) | Corner range | (°) | -20°~ +120° |

| Minimum feed rate mm | mm | 0.001° | |

| Rotary shaft (B-axis) | Corner range | (°) | 0°~ 360° |

| Minimum feed rate mm | mm | 0.001° | |

| Principal axis | Power | kW | 60(Optional44、90、110) |

| Speed | rpm | 0-3000(Optional5000) | |

| Axial jump/radial jump | mm | 0.002 | |

| Grinding wheel size | Outer diameter × width × inner diameter | mm | 400×(10-120)×127mm |

| High pressure cooling | Pressure | bar | >15(It can be selected according to the actual situation) |

| Flow | L/min | >200(It can be selected according to the actual situation) | |

| Positioning accuracy | X,Y, Z axis (full closed loop) | mm | 0.004 |

| Repeat positioning accuracy | X,Y,Z axis (full closed loop) | mm | 0.002 |

400-090-5999

sale@hzmtg.com

公司名称:Zhejiang Hangji Machine Tool CO., LTD

地址:Hangji Building, NO. 50 Xueyuan Road, Xihu District, Hangzhou

电话:400-090-5999

Copyright: Zhejiang Hangji Machine Tool CO., LTD

copyright © 2011-2021 www.hzmtg.com All rights reserved

Zhejiang ICP NO.16031098-1

浙公网安备 33018502001650号