发布时间:2019年12月06日 浏览次数:36389

Recommended by the Economic and Information Bureau of Lin'an District, and after preliminary examination and expert evaluation, MKL7150×10/37 face teeth CNC strong forming grinder developed by Zhejiang Hangji Machine Tool Co., Ltd. has been listed in the first set of products in the key fields of equipment manufacturing industry of Zhejiang Province in 2020, and is the first set of products in Zhejiang Province.

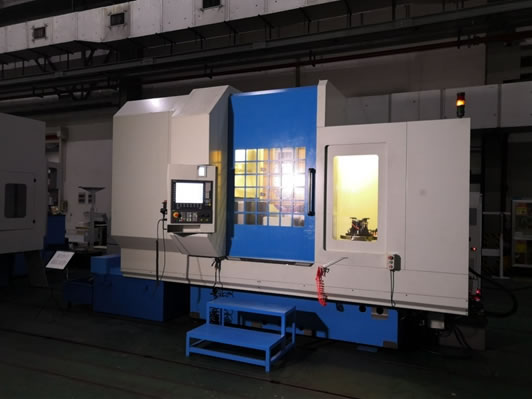

Picture: MKL7150×10/37 Face Teeth CNC Powerful Forming Grinder

MKL7150×10/37 face teeth CNC powerful forming grinder is a new product developed by Zhejiang Hangji Machine Tool Co., Ltd. to respond to the national industrial strategy and successfully developed a variety of powerful slow feed grinding machines. It is mainly used for the processing of the end tooth profile of key parts of the transmission system of commercial vehicles (including output flange, intermediate flange, flange fork, etc.). It adopts the strong slow feed grinding technology, which solves all kinds of problems of broach machining end face teeth, and further improves the machining accuracy and surface roughness of end face teeth. The new product belongs to the 11th item of Key Areas of High End Equipment Manufacturing Industry Development in Zhejiang Province (2019), precision CNC forming grinder in high-end CNC machine tools.

The machine adopts the layout of middle waist column, with high rigidity and high stability, and is equipped with an overhead on-line grinding wheel dressing system to realize one-time strong form grinding of the tooth profile of the end face with a depth of 4mm. The spindle thermal deformation control technology (temperature control, eddy current displacement compensation), high-efficiency strong form grinding technology, and automatic tracking technology of grinding wheel cooling and washing are successfully applied CNC linkage control technology. The research and development has broken through the high-precision expanding and positioning technology of internal spline thread, solved the manufacturing requirements of high symmetry of the end face tooth of output/ middle flange relative to the center of internal spline, controlled the centering rotary runout of internal spline on the fixture of output/ middle flange to be less than 0.01mm, and made the symmetry of the end face tooth profile of output/ middle flange relative to the center of internal spline less than 0.03mm. The stable grinding accuracy is achieved, which provides the overall structure and technical support for the high-efficiency and high-precision grinding of automobile end face gear parts.

The machine tool has been put into use at the user's place, running well, and has been put into mass production as the user's key processing equipment. All the performance indexes of the machine tool have met the design requirements. The technical level of the product is leading in China, reaching the level of similar products in the world, and has the ability to replace imports and participate in international competition.

400-090-5999

sale@hzmtg.com

公司名称:Zhejiang Hangji Machine Tool CO., LTD

地址:Hangji Building, NO. 50 Xueyuan Road, Xihu District, Hangzhou

电话:400-090-5999

Copyright: Zhejiang Hangji Machine Tool CO., LTD

copyright © 2011-2021 www.hzmtg.com All rights reserved

Zhejiang ICP NO.16031098-1

浙公网安备 33018502001650号